Introduction to 3D Printing

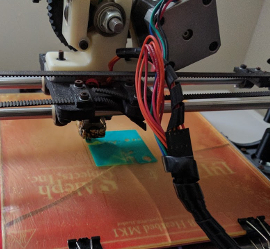

3D printing is the process of creating a three-dimensional object by adding many layers of material together. This process is performed by a computer controlled machine commonly called a 3D printer. This article will primarily be discussing the Fused Deposition Modeling(FDM) method of 3D printing. Most FDM printers will heat up plastic and push it out from a nozzle. This process is called extruding.

Why 3D print?

The first question many people ask when hearing about 3D printing is “Why would you 3D print something?”. As it turns out, there are many reasons to 3D print something including:

- Rapid Prototyping – Since 3D printers are designed to print models from a file, changing a design for prototypes is as simple as updating the model file. Often times in traditional prototyping, changing the prototype would require a hardware change.

- Medical – Ranging from custom prosthetics to 3D printed pills, there are many medical applications of 3D printing.

- Repairs – 3D printing is a great way to print custom parts for repairs that would otherwise be unavailable for purchase.

- Urban Development – Projects such as the Printed Nest that help animals live in highly populated areas.

- Hobby – There’s plenty to learn about electronics, 3D modeling, and 3D printing things is fun!

Getting started

The first step in 3D printing is 3D model STereoLithography (STL) file and converting it into a series of text commands that the printer will understand, called GCODE. The process of converting a STL into GCODE is called slicing, and is performed by a program called a slicer. Often times slicers will talk directly with your printer, sending the GCODE for direct execution. Popular slicer software includes Cura, Slic3r, and Simplify3D.

A STL file for benchy the boat

Much of the excitement around 3D printing comes from finding different things to print. 3D printing design hubs like Thingiverse or Pinshape host STL files that are free to download. Community members can create, upload, or remix different designs. Often top designs are curated for an upcoming holiday or to match a specific theme.

Types of printers

3D printers come in a variety of shapes and sizes. Commercial printers tend to be the most common of 3D printers, as they are often available for purchase online or in stores. The prices and quality can vary from company to company, with the higher end models having very high quality.

The ORDbot Quantum 3D printer

The most popular type of open source printer is called the RepRap. In addition to being open source, RepRap printers have the goal of having as many of their parts be 3D printed as possible. This leads to the unique situation where someone can print parts for a new printer that would otherwise had to have been manufactured.

Choosing your materials

There are several different types of filament that can be used in FDM printing, each with various strengths and weaknesses.

- Acrylonitrile Butadiene Styrene (ABS) used to be the most popular filament type used in 3D printing. It’s low cost, durable, and is easy to extrude from a 3D printer head. ABS requires a relatively high temperature to print around 205°C – 255°C. The major downside of ABS is that it often produces bad smelling fumes and needs to be printed in a well ventilated area.

- Polylactic acid (PLA) has replaced ABS as the most commonly used filament in 3D printing. PLA is biodegradable and is often made from corn starch, making it the environmentally friendly option. In addition to having less of an environmental impact than ABS, PLA prints at a much lower temperature(180°C – 230°C) and does not produce fumes.

- The third most common type of filament is PolyEthylene Terephthalate mixed with Glycerol (PETG). Unlike PLA or ABS, PETG was created specifically for the purpose of being used in 3D printing. It has high flexibility, strength, and the layers stick together much better than ABS or PLA.

Wrapping up

That concludes the basic topics around 3D printing. If you found this article interesting, I encourage you to learn more about 3D printing. It can be a fun hobby and a rewarding endeavor. Happy printing!